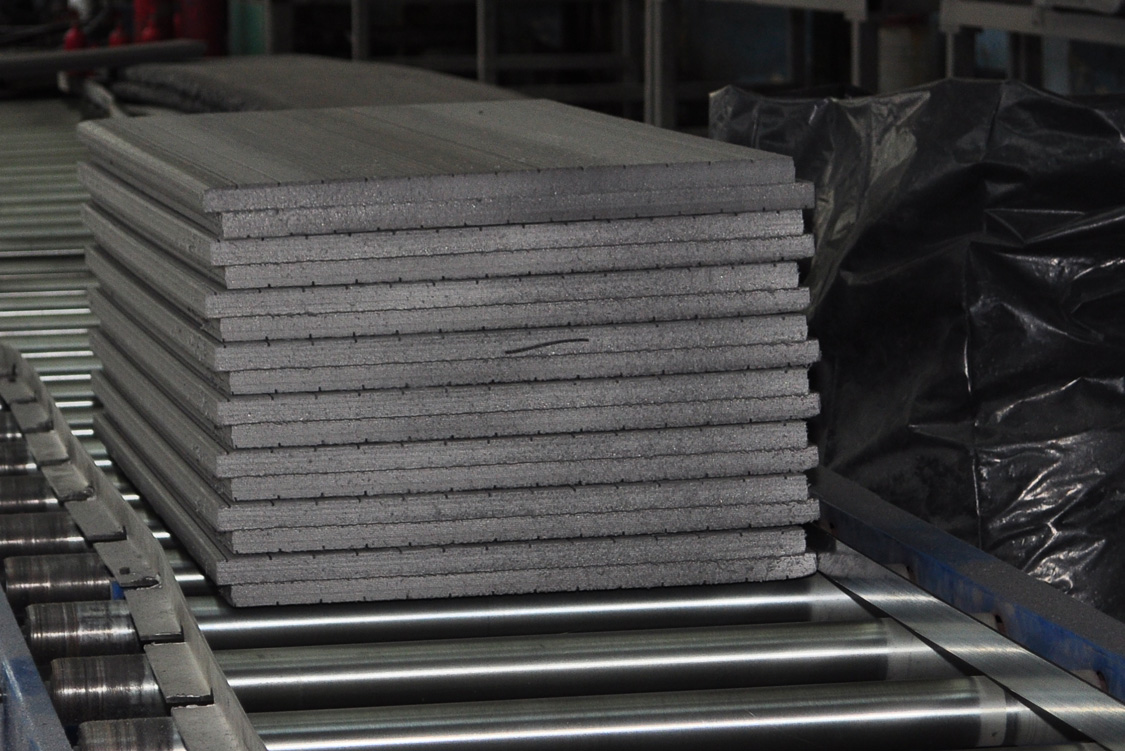

GIAS Grafit XPS extruded polystyrene boards Recommended for both residential and industrial buildings.

The manufacturing process for the GIAS XPS compressed polystyrene is similar to the manufacturing process of styrofoam products (EPS). They both start with the same basic raw material. However, in the case of compressed polystyrene, particles or resin polystyrene particles are entered into an extruder, where they are heated at very high temperatures, until molten. At that time, different additives are added to the molten mixture. For our product, one of these additives is graphite. The GiasXPS slab is easily identifiable thanks to its grey colour caused by a high graphite content. Using the carefully controlled heat and pressure, the plastic mixture is forced through a (compressed) matrix, then left to cool and expand into the desired shape. The resulting foam slab is then cut into the final sizes of the product.

GIAS Grafit XPS is the number one material of choice for builders, engineers and architects, being robust and durable, with a high compressive strength and superior thermal performance.

The high-density GIAS Grafit XPS cell structure allows it to be almost completely waterproof. Typical thermal insulators lose their insulation qualities when in contact with water while GIAS Grafit XPS continues to work as designed, without modifications in its functioning parameters. These features recommend it as the most appropriate solution.

Uses:

- Floor insulation: the GIAS Grafit XPS high compressive strength makes it ideal for insulating a wide range of floors and especially those under great loads such as warehouses, production facilities, car parks, etc. The XPS extruded polystyrene boards can take concentrated loads but can also adapt to uneven surfaces with distributed loads, maintaining their dimensional stability. Also important is the pest free feature and their resistance to soil contaminators.

- Building insulation: GIAS Grafit XPS is ideal for thermally insulating the exterior walls of a building, from the bottom to the top, with no gaps that allow thermal bridging. The exterior wall insulation leads to the retention of heat, reducing energy losses through foundations even further. GIAS GrafitXPS is suited for use on soils with high or medium permeability but also on impermeable soils, as it has excellent thermal-hydro insulation capabilities. Offering the smallest values for the λ coefficient (0.027),GIAS Grafit XPSwith graphite improves the energy rating of your building and significantly decreases the energy used in maintaining thermal comfort.

- Terraced roofs: the GIAS GrafitXPS graphite extruded polystyrene boards are durable, do not rot or decompose. They are installed as an insulation layer on top of the waterproof membrane in order to protect it from inclement weather. Their high compressive strength recommends them for roofs that take heavy loads or constant heavy pedestrian traffic.

Features and benefits:

• Strong and durable, over medium- and long-term

• Extremely light and easy to handle

• High compressive strength

• Low water absorbtion index

• Keeps its thermal insulating properties for a very long time

• Entirely made in Romania

• Environmentally friendly

Available sizes:

• 1250mm (height) x 580mm (width)

Available thicknesses:

• 20mm

• 30mm

• 40mm

• 50mm

• 60mm

• 80mm

• 100mm

• 120mm

Joint shape:

• Edge on edge, for straight edges

• Tongue and groove